Product Info

Elbo Controlli NIKKEN has a wide range of vertical presetter machines which offer the perfect solution to all your needs: all our presetters are versatile and extremely simple to use.

The Elbo Controlli NIKKEN tool presetting machines are able to satisfy the market needs and they solve problems which commonly occur in the workshop. Thanks to a continuous research and development of new technical solutions, we propose tool presetting machines at competitive prices: tool presetters for everyone.

PRESET TABLE TOP

The desktop measuring instrument needs to be placed on the workbench and operated on the workbench, and there are no tools to fix it on the table. It is the entry-level model of the measuring instrument. Elbo Controlli NIKKEN currently has four desktop measuring instruments including Sethy SIX, E346V+, E346+ and E236+.

PRESET STAND ALONE

The stand-alone measuring instrument is equipped with an independent base, so it can be placed directly on the ground without the need to prepare an additional workbench. The advantage of this type of measuring instrument is that it has a sturdy structure and can reduce errors in measurement results caused by interference from external factors during measurement. Elbo Controlli NIKKEN has a total of 14 models of independent measuring instruments for customers to choose from, including E68LA IS, E68LA, E68L IS, and E68L.

GESTIONE UTENSILI

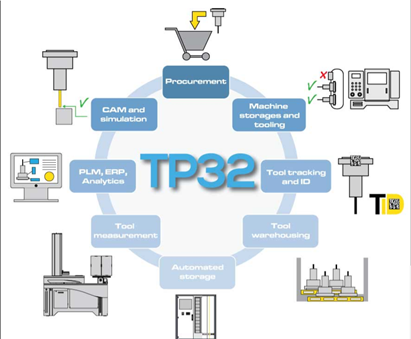

All series of measuring instruments are equipped with customized software designed and developed by Elbo Controlli NIKKEN, and can also be installed with tool data management software TP32 and TID.

The tool management system is easy to use and helps users manage and integrate tool information to effectively improve enterprise production efficiency.

DISTRIBUTORE AUTOMATICO UTENSILI

The automated tool magazine can ensure the availability of materials 24 hours a day and reduce purchasing procedures for cost control. The automated tool magazine has more than 400 built-in compartments, and the compartment sizes can be customized to allow users to easily manage and organize all materials. Data synchronization and system integration can be achieved through TP32 software.

MISURATORI

During precision machining, in order to ensure that the tool does not cause concentric errors, a tension gauge can be used to monitor the clamping force of the tool holder to avoid problems with poor accuracy. The tensile force measuring instrument can be used on either the operating base or the tool measuring instrument, allowing the operator to quickly and easily measure the spindle clamping force of the machine table and measuring instrument.